| Brand | OEM, ODM |

|---|---|

| Size | OEM standard size |

| Material | HT250, G3000, GG25, High carbon |

| Hardness | 180-240 |

| Surface treatment | As customer request etc. |

| Intensity | ≥250 MPa |

| Transportation | Sea or Air |

| Certification | IATF16949, ISO9001, ISO14001, ECE R90, AMECA |

| Package | Neutral box, MIXHY color box or customized |

| Main Market | Global market |

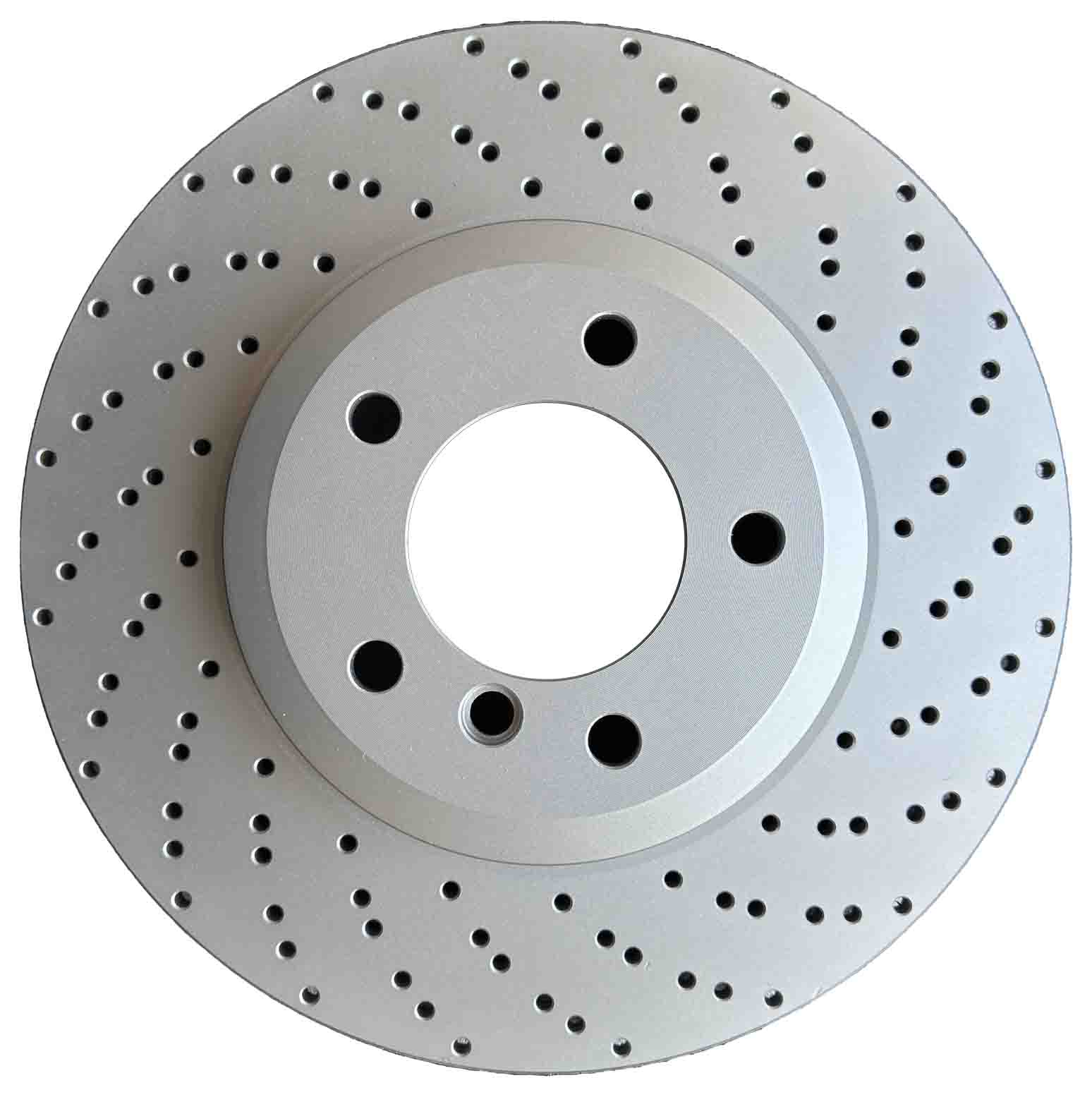

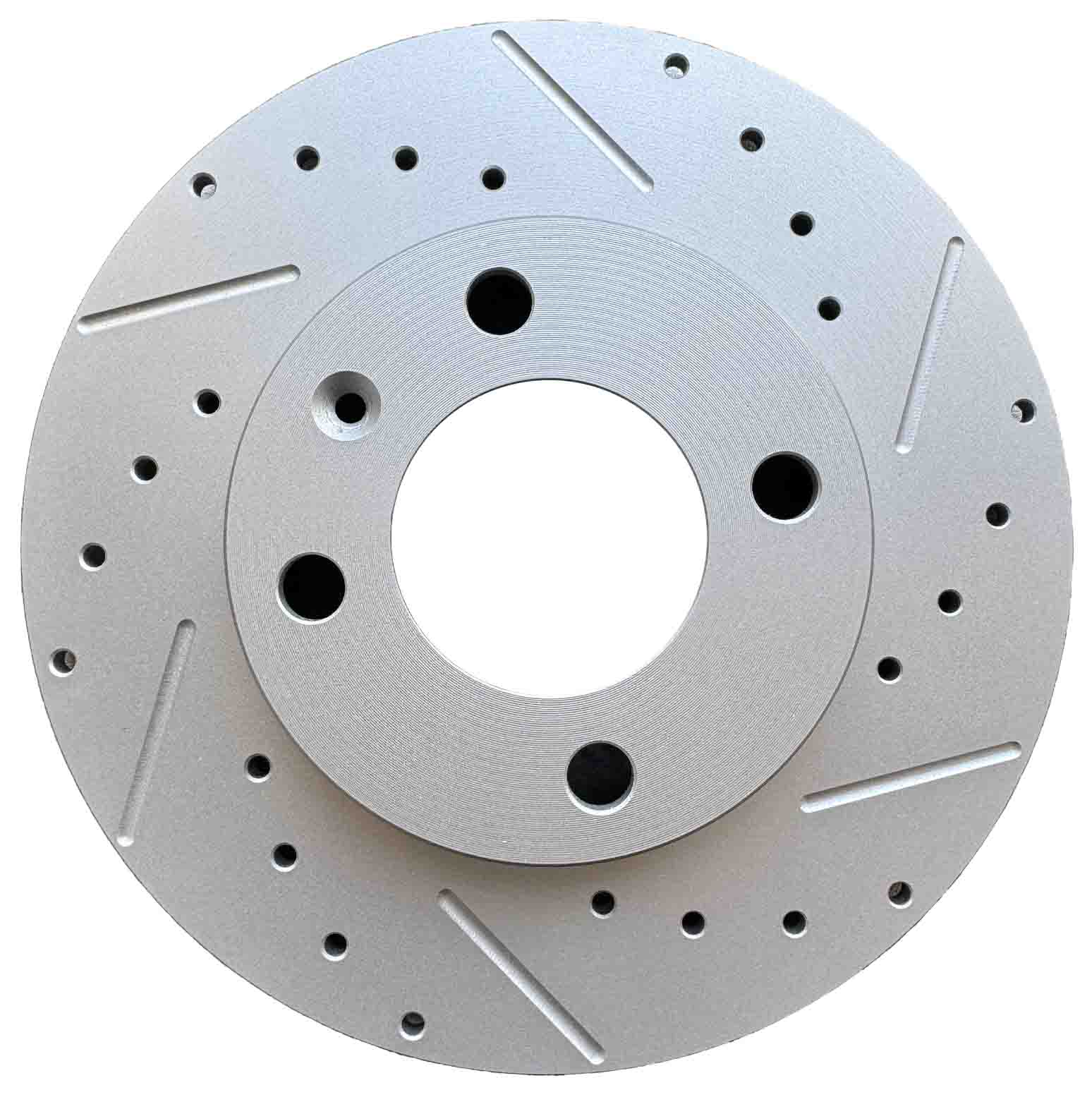

Our brake discs are constructed from premium materials including cast iron, cast aluminum alloy, and advanced ceramic composites. Each material type is engineered to deliver specific performance advantages,such as superior heat dissipation, lightweight design, or extreme durability, tailored to meet different vehicle categories and driving scenarios.

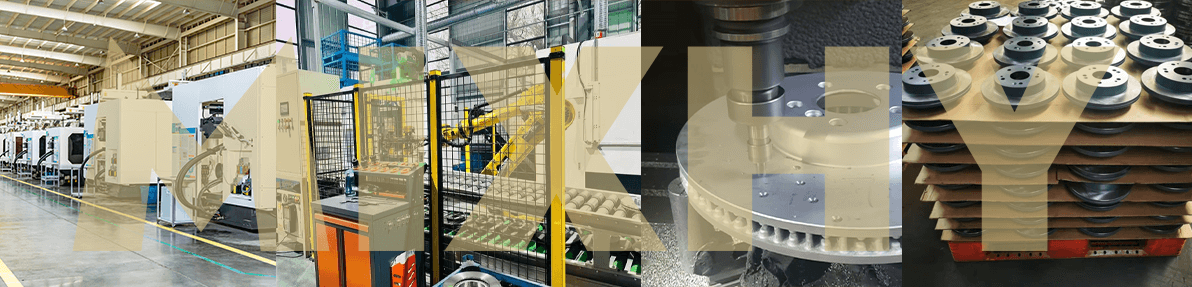

Our manufacturing process incorporates precision heat treatment techniques, including quenching and tempering cycles. This proprietary method significantly enhances thermal resistance and structural stability,ensuring consistent braking performance even under high-speed or prolonged heavy use conditions.

Absolutely. All our brake discs comply with globally recognized safety standards including DOT (Department of Transportation) and ECE R90 certifications. Additionally, our production facilities maintain ISO 9001:2015 compliance, ensuring strict quality control throughout the manufacturing process.

The service life varies based on driving habits and operating conditions. Under normal use, our brake discs typically last 2-5 years or 50,000-100,000 km. Regular maintenance, including inspections and timely pad replacements, can maximize longevity and performance.

Yes, we specialize in custom brake disc manufacturing. Our engineering team can develop solutions with bespoke dimensions, specialized coatings, or performance-enhancing features to meet unique requirements. Contact us with your specifications for a tailored quotation.

Unusual braking noise often stems from uneven disc surfaces or worn brake pads. We recommend periodic inspections to ensure proper disc-pad alignment and timely replacement of worn components. Professional resurfacing or replacement can restore quiet, efficient operation.

Our discs feature advanced corrosion protection technologies including phosphate coatings and galvanized finishes. These treatments provide long-term resistance to rust and environmental degradation, maintaining peak performance in all weather conditions.

Signs of replacement include visible cracks, excessive wear beyond manufacturer specifications, disc warpage causing vibration, or reduced braking responsiveness. Regular inspections are critical for safety and optimal vehicle performance.

Lead times depend on order complexity. Standard products are typically shipped within 1-4 weeks after order confirmation. Custom-engineered solutions may require additional time for design validation and production.

We offer comprehensive post-purchase support including installation guidance, technical troubleshooting,and warranty services. Our dedicated customer service team is available to assist with any product-related questions or concerns.